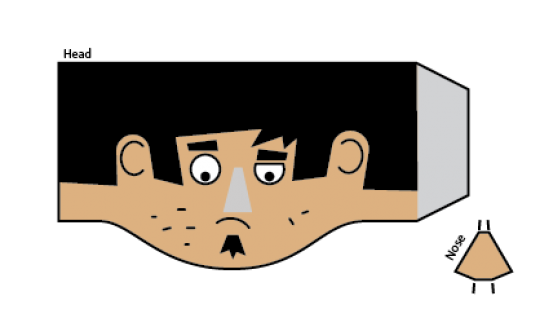

I asked QuackYeah to customize it to Boston area.

His first version was a little too sunny and mild.

Version 2 got angrier, grittier, unshaven.

I knew I'd also have to make the transition away from paper.

Hooking Matt up to a Servo

And hook it up to a servo.

There wouldn't be much of Gentleman Jack left, beyond the inspiration.

My first attempts were very rough: lots of scotch tape.

But eventually, I started swapping in new things:

From ServoCity -- a 1/4 inch steel rod. and a unit that could connect it to a standard servo.

C1 Spline Servo to 1/4" Shaft Coupler (Set Screw) -- https://www.servocity.com/24t-set-screw-servo-shaft-coupler

1/4" Stainless Steel D-Shafting -- https://www.servocity.com/0-250-1-4-stainless-steel-d-shafting

And just for good luck, a new servo, which I knew would fit. -- https://www.servocity.com/hsr-1425cr-servo

A Material Upgrade

The sprocket had to be more than paper -- so I started working with Inkscape.

And the laser cutter

My new sturdy material: 1/8th inch birch plywood. Easy on the laser cutter.

I also tapped into my favorite internet box sites.

Going Rotary

Along the way I started using a Dremel, a handheld rotary device that allowed me to cut and shape some of the more awkward edges. I found a bunch of them in a drawer at Cambridge Hackspace. The bits were all over the place, more for polishing and sanding. It took a trip to my neighborhood hardware store to get the bit I needed.

It wasn't cheap: around $20.